STRUCTURAL INSULATED PANELS

Over the years, as building

techniques have evolved, Tim has

found a way to incorporate his

tried and true methods and old-

school work ethic with updated

construction technology. One

new approach he has mastered

is the use of Structural Insulated Panels,

or SIPs. Tim first learned about SIPs when developing plans to build his own house in 2000. He wanted to build a unique house that could withstand use by his four children, as well as a place to operate his business. After researching the benefits of using SIPs in construction, he was sold on the strength and energy savings they could provide.

He completed the house, his first SIP build, in 2001, and has since utilized the panels

to construct dozens of projects. The panels have allowed him to pass on the benefits of using SIPs to his customers and create quality projects including homes, garages, and room additions.

Building with SIPs has unlocked new potential in the development of projects, allowing designs to become energy efficient while still providing the ability to customize them to fit the homeowner’s needs and wants. Once these benefits have been realized, many customers have returned over the years with other projects to build!

Tim and his crew take pride in every project they do, bringing experienced craftsmanship to a variety of project types: new homes, shops, garages, additions, remodeling, kitchens and bathrooms.

WHAT IS A SIP?

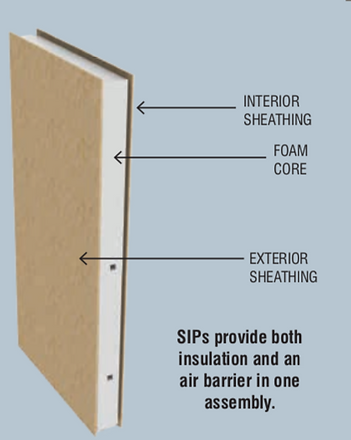

Structural insulated panels are high- performance building panels used in exterior walls, roofs, and floors. SIPs are made by EPS, Inc. The panels are made by sandwiching a core of rigid foam insulation between two skins of oriented strand board (OSB). SIPs create a living environment that is more comfortable because of reduced air flow and noise.

SIPS SAVE ENERGY AND MONEY

Building with SIPs creates a superior building envelope with high thermal resistance and minimal air infiltration. SIPs are one of the most airtight and well insulated building systems available, making them an inherently green product. An airtight SIP building will use less energy to heat and cool, allow for better control over indoor environmental conditions, and reduce construction waste.

SIPS SAVE TIME AND LABOR

SIPs are ready to install when they arrive at the job site, eliminating the need to perform individual operations of framing, sheathing, and insulating stick-framed walls. This saves a significant amount of on-site labor.

Z-BEST CARPENTRY PARTNERS WITH EPS WHERE EXPERIENCE AND HIGH TECH COMBINE

Energy Panel Structures, Inc. (EPS) was established in 1981 as a wholly-owned subsidiary of the MacArthur Company of St. Paul, MN.

The company was started in Albert Lea, MN. After three expansions, the company moved in 1988 to Graettinger, Iowa to a new 40,000 square foot plant designed specifically for the manufacture of insulated panels. Since the move to Graettinger, EPS has expanded three times, adding 3,000 square feet for a door manufacturing facility and another 7,000 square feet to increase the finished goods storage capacity.

The latest expansion of 30,000 square feet to the main manufacturing space brings the total facility to 110,000 square feet on an 8-acre tract. In 2010, EPS purchased a manufacturing facility in Perryville, Missouri. Along with the manufacturing capability, this location boasts additional engineering and sales support for EPS and the network of dealers.

The EPS family expanded again in 2013 with the addition of Fingerlakes Construction (FLC), headquartered in Clyde, New York. FLC also specializes in the construction of custom homes, commercial and agricultural buildings.

EPS is the nation’s largest manufacturer of structural insulated panels with a network of over 400 builders. EPS manufactures complete building packages for new homes, agricultural buildings, and commercial buildings whether SIP or post-frame built.

The company takes pride in the latest technology within the company and passing that technology and training to builders like Z-Best Carpentry.